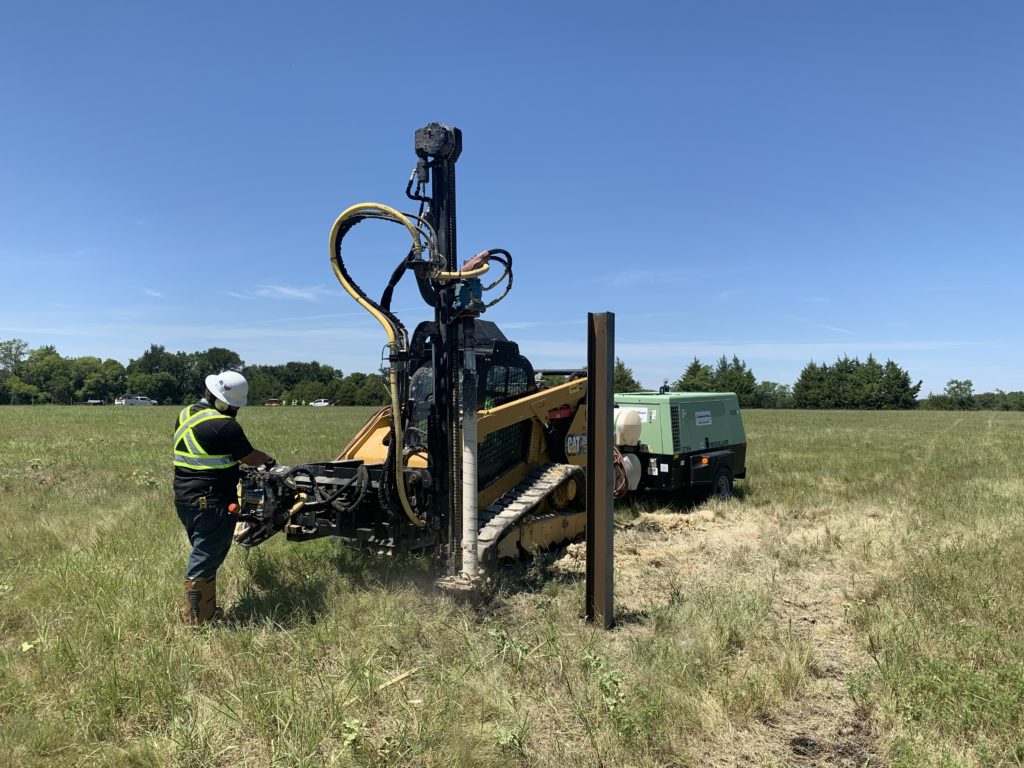

4 Things to Consider when Selecting the Compressor to Run Your Down The Hole Hammer

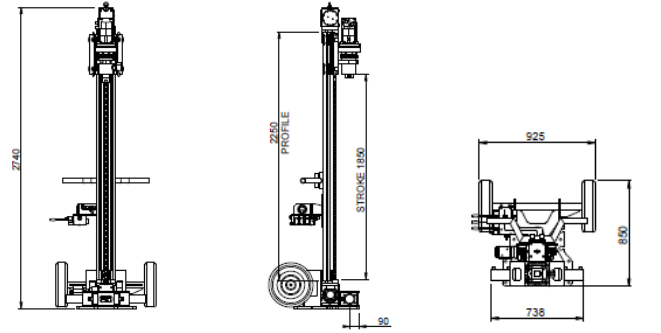

1) Hammer Size and Specs

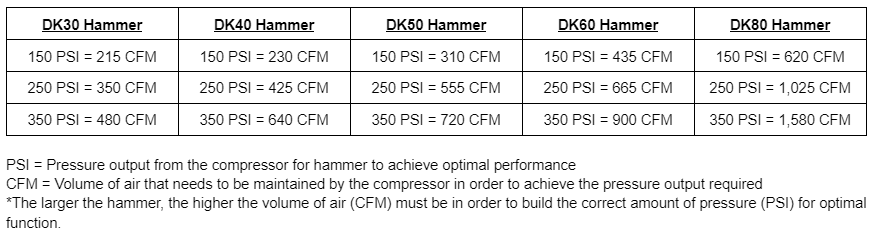

The below specifications outline the requirements for the most common Down the Hole hammer options offered at WORD Rock Drills. Each of these hammers require a 150 PSI minimum for optimum output. Increasing the CFM and corresponding PSI will increase the capacity of your hammer for the best drilling capabilities.

*Above reference chart specific to DK hammers purchased through WORD Rock Drills. Please verify the PSI and CFM requirements of your hammer make/model before moving forward with a compressor rental or purchase.

2) Production Requirements

Compressor size has a significant impact on the efficiency of your Down The Hole hammer. Finding a balance between efficiency and compressor size can be a thin line and depends heavily on the priorities of the project. For example, if time and speed are a top concern, then investing in a stronger compressor might cost more to run but it will help you move through holes quicker. Alternatively, if you are looking for a more budget-friendly solution, smaller compressors are less expensive to rent or own and do not require as much fuel. Therefore, you might choose to run the minimum size compressor for your hammer in order to save on cost. In most cases, increasing the size of your compressor to achieve the higher end of the PSI range for the hammer can lead to a 40% or more increase in drilling capacity.

3) Altitude

A key variable in the selection of a compressor to run the hammer on your machine is the altitude of your project site. Due to the thinner air at higher altitudes, compressor productivity and capacity can be impacted. This is important to consider because lower compressor output will change the behavior of your Down The Hole hammer and could cause the hammer to cease function altogether. A good rule of thumb to prevent this variable from causing problems on your job site is to always check the compressor specs at altitudes over 8,000ft. The specs for the compressor should outline functioning PSI at various altitudes and help you to determine if the PSI is adequate for the hammer you are running.

4) Availability

It is very common for customers to rent their compressors. Considering the price of compressors, maintenance, and transportation, rental just makes more sense than owning the machine outright. However, renting adds another layer of complexity when it comes to determining what compressor to acquire from one job site to the next and the availability of the compressor you need. When it comes down to it, the main consideration for any compressor should be around the PSI output and the specs of the hammer.