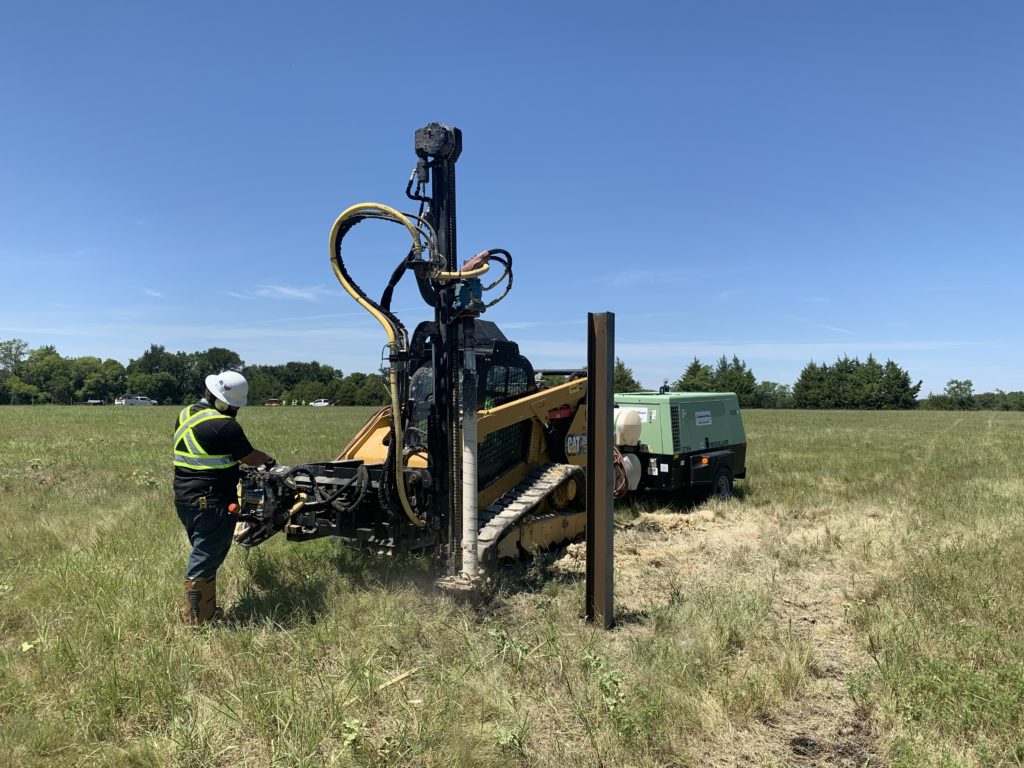

7 Tips for Maintaining Your Skid Steer and Excavator Attachment Going Into Summer

1. Look for Wear on your Centralizer Gates

As a key component in the movement of the drill, your centralizer gates wear down throughout a job. Check your centralizer gates between jobs and replace them when they start to wear down to keep your machine in peak condition.

2. Grease, Grease, Grease

Your drill has many grease points that prevent early wear and allow your machine to run smoothly. Regular greasing is important to maintain the machine during use. Sometimes, when your drill is doing work on the job site, common grease points are overlooked during daily maintenance. Take advantage of the time between jobs to look over your machine closely and make sure everything is well-greased.

3. Check Nylatron Wearpads

Located on the mounting assembly for your Word Rock Drills motor, the Nylatron Shims on your rock drill allow your motor to move smoothly along your feed rail. Over time, these Nylatron Wearpads become thin due to the constant movement. Regularly replacing these wearpads is essential for maintaining the longevity of your machine.

4. Give your Hydraulic Hoses the “Once Over”

Hydraulics are the lifeblood of your WORD drilling attachment. Because of this, it’s important to keep your hoses in top shape! Check that all of your hose connections are tight and that your hoses are well managed so that they do not get caught on anything while drilling or in transport.

5. Stock Up on Biodegradable Rock Drill Oil

Rock drill oil makes the world go round. Well, not really … but it is a key component to a smooth functioning drill! Take this opportunity for maintenance to give us a call and stock up on Biodegradable Rock Drill Oil for the season to ensure that you don’t run out while on the next job.

6. Set Chain Tightness

The feed rail chain on your WORD Rock Drill can become loose periodically. The natural movement of the machine during drilling leads to wear within the primary sprocket of the feed rail chain. This sprocket contains a 1/16th brass bushing which is often the cause of a loose chain. When testing your chain tightness first check to make sure the brass ring within the sprocket is in place and not showing signs of wear. You can then proceed to tighten the chain as usual. Test the tension by moving the drifter all the way forward and checking the rigidity at the middle of the chain.

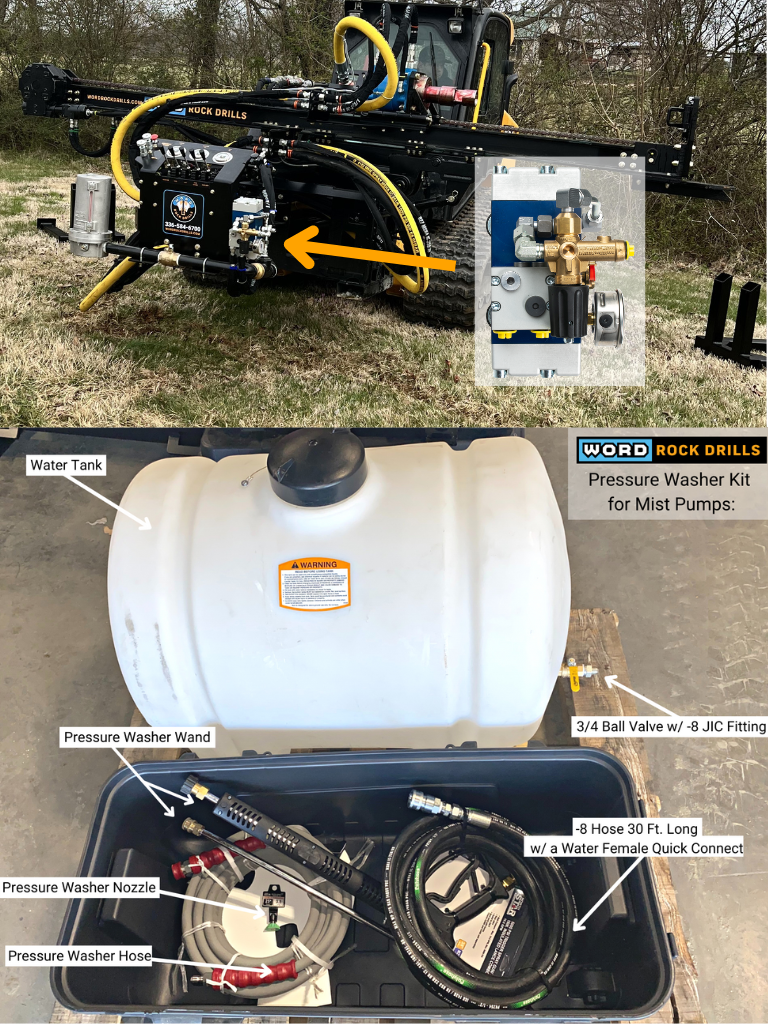

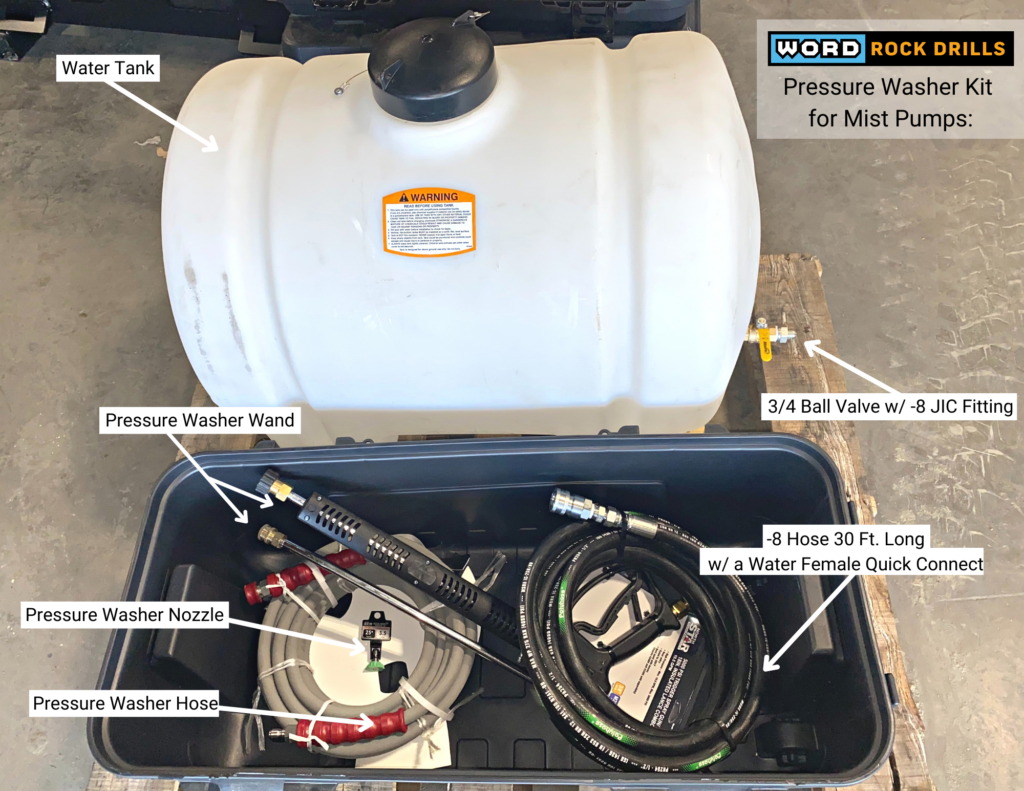

7. Take Advantage of your Mist Pump

Did you know that the mist pump accessory on your rock drill can double as a pressure washer? It sure can! Springtime is a great opportunity to take advantage of this additional feature to clean your machine thoroughly before it heads out to the next job. Keeping a clean machine is key to the lifetime of the unit, allowing you to spot any potential maintenance point early and keep everything running smoothly.

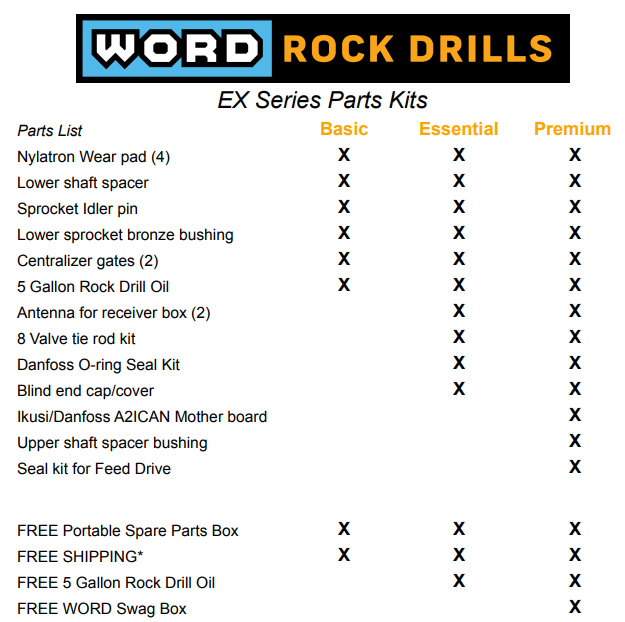

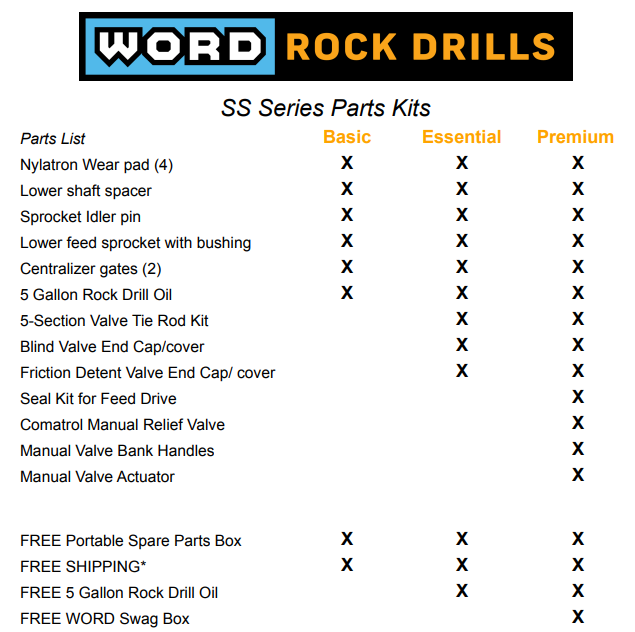

Ready to Stock Up for the Season?

Contact our sales team to snag a Parts Kit!