If you’re using a rock drill with a down-the-hole (DTH) hammer, you know that the shock sub is a crucial component in your drilling setup. This small but mighty piece of equipment minimizes backforce while drilling, ensuring that your drill head operates efficiently and stays in good condition. However, like all equipment, shock subs require regular maintenance to continue performing at their best. Here’s what you need to know about maintaining your shock sub to maximize its effectiveness and lifespan.

When to Schedule Maintenance

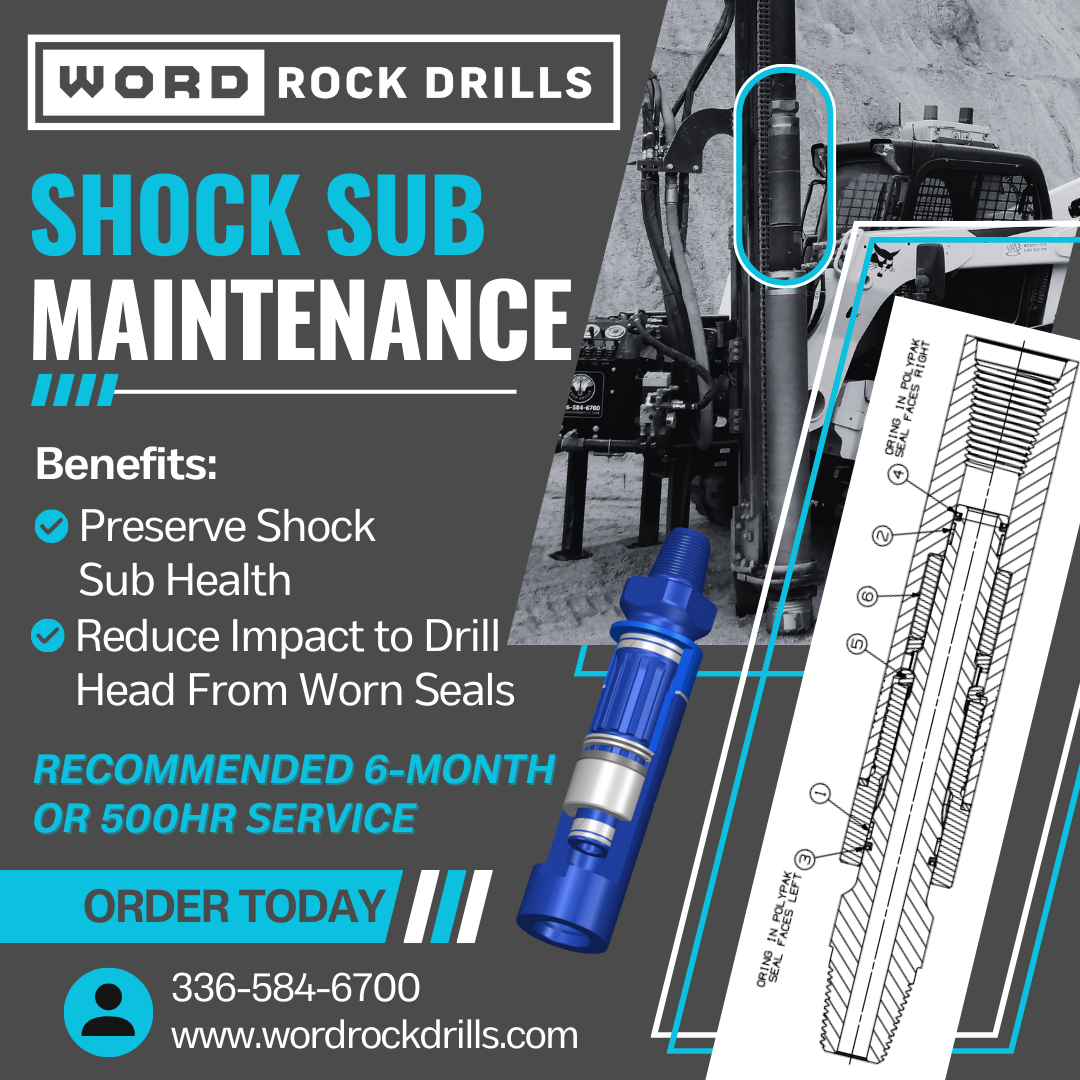

The manufacturer’s recommendation encourages performing maintenance on your shock sub every 6 months or after 500 hours of use, whichever comes first. Due to the nature and function of the shock sub, there are no outward signs when the internal seals begin to wear out, however, sticking to this schedule ensures that your shock sub stays in top shape, effectively minimizing the shock and vibration transmitted to the drill head and other components during drilling operations.

Why Regular Maintenance is Crucial

Although there may be no outward signs indicating that maintenance is needed, the internal components of your shock sub, particularly the seals, are subject to wear and tear over time. As these seals wear down, the shock sub becomes less effective at absorbing vibrations and minimizing backforce. This can lead to:

- Reduced Performance: A shock sub that isn’t functioning optimally can cause increased vibration and impact on the drill head, reducing drilling efficiency.

- Potential Damage: Operating when your shock sub is not at peak performance increases wear on your drill head and other components, leading to costly repairs and downtime.

What Happens During Maintenance?

During the recommended maintenance, the focus is primarily on replacing the seals within the shock sub. These seals are critical in ensuring that the shock sub can perform its function of absorbing force during drilling. The maintenance process typically involves:

- Disassembling the Shock Sub: This allows for a thorough inspection of all components, ensuring there is no hidden damage or wear.

- Inspecting Seals and Components: The seals are checked for signs of wear, cracks, or damage. If necessary, they are replaced to restore the shock sub’s ability to minimize vibrations.

- Reassembling and Testing: After the seals are replaced, the shock sub is reassembled and tested to ensure it functions correctly.

Benefits of Regular Maintenance

- Extended Equipment Life: By regularly maintaining your shock sub, you ensure that your drill head and other components are protected from unnecessary wear and damage.

- Reduced Downtime and Costs: Like an oil change in your car, preventive maintenance reduces the likelihood of unexpected breakdowns, helping you avoid more costly repairs and downtime.

- Optimal Drilling Performance: A well-maintained shock sub ensures smooth and efficient drilling, improving productivity and reducing operator fatigue.

Conclusion

Maintaining your rock drill shock sub every 6 months or 500 hours is a small investment of time and resources that pay off in the long run. Not only does it help keep your drilling equipment in optimal condition, but it also protects your investment by preventing costly repairs and downtime. If it’s been a while since your last shock sub maintenance, now is the time to schedule it. Preserve the health of your shock sub and keep your drilling operations running smoothly!

For more information or to place an order for your sock sub maintenance kit, contact our sales team today! Your equipment deserves the best care—let us help you keep it in top shape.