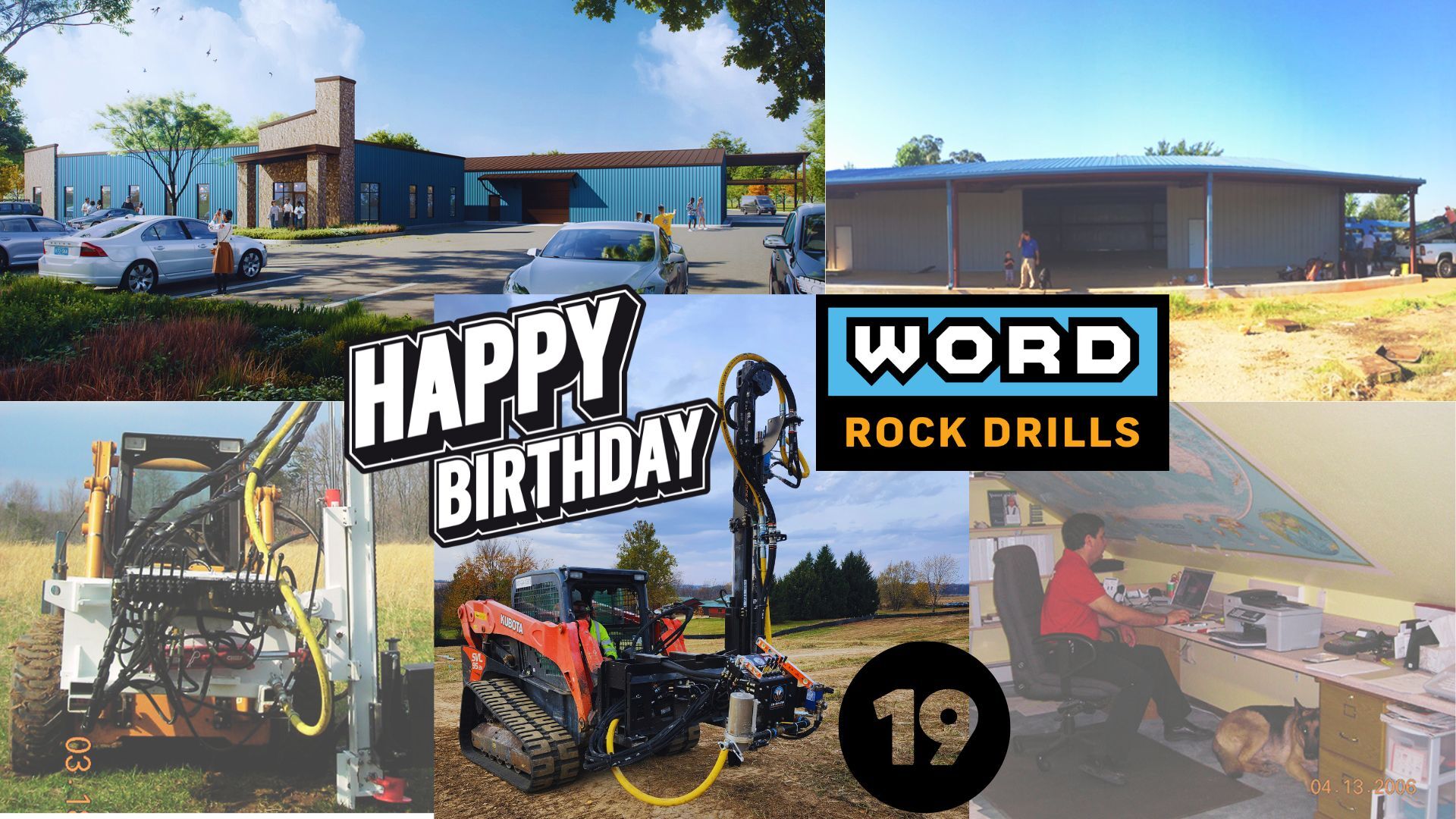

We’re celebrating 19 years of innovation, growth, and drilling excellence at WORD Rock Drills! What started in a garage back in 2006 has transformed into a thriving, women-owned rock drill manufacturing company with a dedicated team, an exciting future, and a whole lot of personality. To mark this milestone, here are 19 fun and interesting facts about WORD Rock Drills that showcase who we are, what we do, and where we’re headed!

1. Humble Beginnings with Big Dreams

Just like Apple and Microsoft, WORD Rock Drills started in a garage. From those early days, we built our first hydraulic drill attachment in 2009 for a fencer in Texas—and we haven’t stopped innovating since!

2. Women-Owned and Growing Strong

We are a proud women-owned rock drill manufacturer, and our team has grown to 23 rockstar members who keep our drilling attachments moving and customers satisfied.

3. Assembled in America, Built for the World

All of our hydraulic drilling attachments are assembled in the USA, using high-quality parts sourced from around the world to ensure top performance and durability.

4. Customization is Key

With over 40 different configurations available, our rock drills are designed to meet a variety of customer needs. Plus, additional accessories allow for even more customization!

5. From North Carolina to Japan

Our drills are making an impact worldwide! Our farthest drill traveled all the way to Japan to serve within the solar industry.

6. A Facility That’s Growing With Us

Currently, we build our drills in a 6,000 sq. ft. facility, BUT by the end of 2025, we’ll be moving into our new 10,000 sq. ft. space!

7. Smarter Storage for Faster Service

80% of our parts inventory is housed in a European-inspired vertical storage unit, allowing us to efficiently store and retrieve components for building drills or fulfilling orders.

8. Fast Shipping, Every Time

We guarantee that all in-stock parts ship within 24 hours of being ordered, ensuring our customers experience minimal downtime.

9. Trade Show Shenanigans

Did you know that we once brought a mechanical bull to a trade show and handed out custom western belt buckles to everyone who dared to ride. Because why not?

10. The Ultimate Trade Show Display

We custom-built a 20’ shipping container to use as a trade show display, complete with a bar and a second-story observation deck. We like to keep things exciting!

11. Our Production Team is Unstoppable

In 2024, our seven-person operations team built an impressive 164 rock drills—talk about efficiency and dedication!

12. Making a Difference in Disaster Relief

WORD currently has NINE drilling attachments being used by various companies to assist with Hurricane Helen relief efforts in Asheville, NC.

13. Durability That Stands the Test of Time

The very first WORD drilling attachment, built in 2009, is still going strong, drilling holes across Texas after 15 years of hard work!

14. Giving Back Globally

In 2024, we sponsored the distribution of Bibles through missions and ministries, reaching over nine countries and making an impact worldwide.

15. Operation Christmas Child Mission

Each year, our team packs 250 shoeboxes for the Samaritan’s Purse Operation Christmas Child Mission. Then, in December, we take a day to travel to Charlotte and volunteer at the shoebox distribution center.

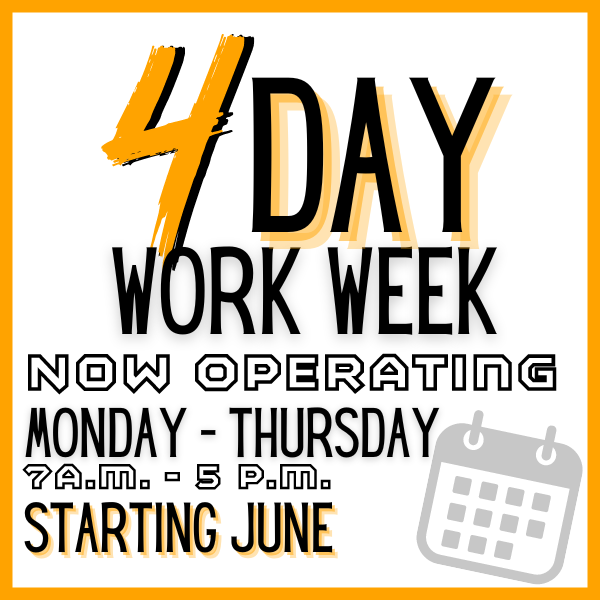

16. A Work Schedule That Works for Life

We believe in work-life balance, which is why we operate on a four-day workweek! But don’t worry—our on-call team is available on Fridays for any urgent needs.

17. Innovation and Adaptability

Our hydraulic rock drills have been used in diverse industries, from retaining walls below sea level to slope stabilization at the top of mountains, WORD is always adapting to meet our customers’ unique needs.

18. Built for Tough Conditions

WORD Rock Drills are engineered to withstand the harshest job sites, from rocky terrains to extreme weather conditions, even drilling within the Arctic Circle.

19. Looking Ahead to the Future

With a new facility on the horizon, a dedicated team, and continuous innovation, the future of WORD Rock Drills looks brighter than ever!

Why Choose WORD Rock Drills?

When it comes to reliable, high-performance hydraulic rock drills, WORD Rock Drills is a trusted name in the industry. Our commitment to quality, innovation, and customer service ensures that our drilling attachments provide long-lasting performance in even the toughest conditions.

We’re so grateful to everyone who has been part of our journey—our customers, our team, and our supporters. Here’s to many more years of drilling, growing, and making an impact. Happy 19th birthday to us!

Stay Connected

Want to learn more about our rock drilling solutions? Contact us today or follow us on social media to stay up to date with the latest from WORD Rock Drills!