- Free Rock Drill Coloring Pages to Pass the TimeGrab your free coloring page below and GET CREATIVE! We will have new coloring pages throughout the year so be sure to check back in to make sure you don’t miss anything! Tag us on social media with your coloring page! We’d love to see it! Rockin’ Women in Construction… Read more: Free Rock Drill Coloring Pages to Pass the Time

- Spring Cleaning: Rock Drill Edition7 Tips for Maintaining Your Skid Steer and Excavator Attachment Going Into Summer 1. Look for Wear on your Centralizer Gates As a key component in the movement of the drill, your centralizer gates wear down throughout a job. Check your centralizer gates between jobs and replace them when they… Read more: Spring Cleaning: Rock Drill Edition

- 5 Creative Solutions to Random Things you Run Into While Drilling1) Sub Zero Temperatures? You Won’t Be the Only One Who Needs to Bundle Up! When the temperature begins to creep below freezing, there are a few things that you need to do to keep your drill running smoothly. If you need to use the water mist dust suppression system… Read more: 5 Creative Solutions to Random Things you Run Into While Drilling

- John 1:1-4; The Meaning of WORD“In the beginning was the Word , and the Word was with God, and the Word was God. 2 He was in the beginning with God. 3 All things were made through him, and without him was not any thing made that was made.” John 1:1-4 We often get the… Read more: John 1:1-4; The Meaning of WORD

- Get the Reach You NeedIncrease the Versatility of your Jobsite with a Drilling Attachment When it comes to drilling in hard-to-reach places, the conversation typically turns to limited access in terms of compact spaces that limit your equipment options. However, creative thinking isn’t just reserved for your limited access sites. Almost every job site… Read more: Get the Reach You Need

- Drilling Do’s and Don’tsDrilling Do’s and Don’ts for Team Safety and Drill Efficiency Do’s DO Have properly installed whip checks on both ends of your airline Having properly installed whip checks is important for the safety of both the drill operator and anyone else around the machine during operation. Whip checks are an… Read more: Drilling Do’s and Don’ts

- Oh, the Places You Can Go!From Mountains to Caverns and Even the Arctic Circle Enter the World Of Rock Drilling with WORD It’s always an interesting conversation among our team when a customer comes to us with a project that is a little out of the ordinary. These are our sales teams’ favorite calls to… Read more: Oh, the Places You Can Go!

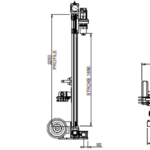

- Choosing the Best Accessories for Your Rock Drill AttachmentTop 10 Rock Drill Attachment Accessory Options at WORD Rock Drills 10. Energy Chain The longer your feed rail, the more important the addition of the energy chain becomes to the overall effectiveness of your machine. We offer a range of feed rail options from 6′ to 24′ for our… Read more: Choosing the Best Accessories for Your Rock Drill Attachment

- Christmas in July: Rock Drilling EditionA typical day at the WORD office in May brought a not-so-typical customer to the sales team for a rock drilling solution. This customer, the owner of a Christmas tree farm, had found himself in a rocky situation while preparing for the upcoming tree harvesting season. While in the process… Read more: Christmas in July: Rock Drilling Edition

- Tips for Compressor Selection4 Things to Consider when Selecting the Compressor to Run Your Down The Hole Hammer

- Download Our Brochure

- Line Em’ Up, Rack Em’ DownInstalling solar ground mount systems becomes easy when you have a WORD Rock Drill in your equipment toolkit. The Solar Industry is booming and one thing that we hear way too often is “how do I get these things in the ground”? When it comes to commercial and utility scale… Read more: Line Em’ Up, Rack Em’ Down

- 3 Big Reasons to Work with a Certified WOSBDid you know WORD Rock Drill is a Women Owned Small Business (WOSB)? Yes! We officially became a certified WOSB in early 2021 after seeing the value this certification could bring to our customers. Here are just a few of the ways your company can benefit from working with a… Read more: 3 Big Reasons to Work with a Certified WOSB

- WORD 2021 Top 102021 was a BIG year for WORD! Learn more about what we got up to this year with our team in the WORD Top 10 of 2021!

- Off to the RacesIFCEE 2021: The Most Anticipated Drilling Trade Show in 2021

- A Season of GivingWORD Rock Drills 3rd Annual Operation Christmas Child Shoebox Packing Party!

- Frequently Asked QuestionsFAQ’s about WORD Rock Drills: Will a WORD Rock Drills work for my project? Will I need to hire and experienced driller to operate my WORD Rock Drill? Find the answers to these questions and MORE!

- The Multi-ToolGet to know the drill that does MORE!

- Tips for Getting Started with your WORD Drilling Attachment7 Things You Want to Have On-Hand when Hooking Up Your WORD Drilling Attachment

- Tips for Construction Opening Post COVID-194 Things for Construction Companies to Consider as the U.S. Makes its Way through the Re-Opening Phases 1. What will the New Normal Look Like Like any major event, the “normal” we enter into as the U.S. moves through the re-opening phases will not be the same “normal” that we… Read more: Tips for Construction Opening Post COVID-19

- On The Job Versatility: Crane DrillingLimited Access?? Maybe Crane Drilling Will Do It?

- Equipment Maintenance: Maximize Down-time7 Ways to Maintain your Drilling Equipment Between Jobs 1. Grease Your drill has many grease points that prevent early wear and allow your machine to run smoothly. Regular greasing is important to maintain the machine during use. Sometimes, when your drill is doing work on the job site, common… Read more: Equipment Maintenance: Maximize Down-time

- 3 New Things for WORD at ConExpo 2020Let’s be honest. ConExpo 2020 was something none of us expected. Between the rain, coronavirus, and a shortened show; this years ConExpo was not lacking in drama. However, despite the strange circumstances of the show this year, there was an amazing turnout! The smaller number of attendees actually turned out to… Read more: 3 New Things for WORD at ConExpo 2020

- ConExpo 2020; A Great Show for Small BusinessesThe excitement for ConExpo is something that builds for months. There are ads in every construction magazine for “Big Reveals” and exciting activities that keep the event buzzing. Leading up to the 2020 ConExpo was no different, everyone was excited, ready to show off new products and booths. Things played… Read more: ConExpo 2020; A Great Show for Small Businesses

- Making a Way for Easier Limited Access DrillingYou’ve got to get the job done! You’ve beaten the competition and the contract is yours but now its time for logistics. Limited access drilling it tricky. Are you trying to get a drill rig through a doorway? Down some stairs? Helicoptered onto a remote location? Struggling with accessibility in… Read more: Making a Way for Easier Limited Access Drilling

- Foundation Drilling NewsWe were featured in Foundation Drilling. Read the article to learn more.